The team of researchers working on LieberLieber’s collaboration with CDL (Christian Doppler Laboratory of TU Wien) presented its first case study in the form of a mobile robot. The core of development is focused on targeted data reduction that allows the analysis of real-time system behavior.

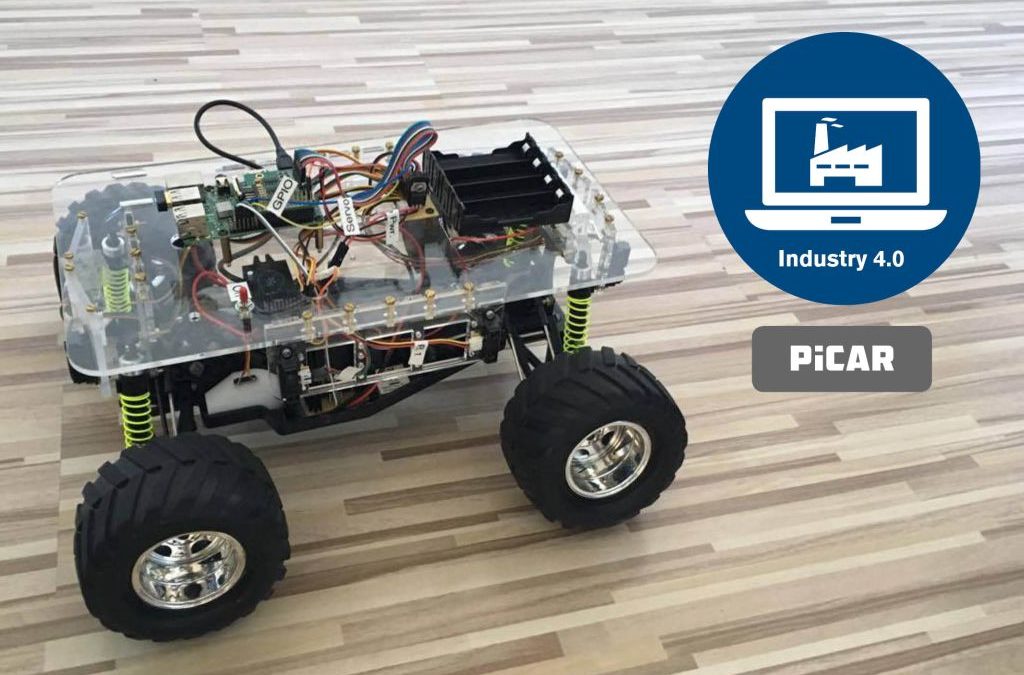

The aim of LieberLieber’s joint research on the “CDL for model-integrated intelligent production” (CDL-MINT) project is to convert live data streams generated in Industry 4.0 scenarios directly into models. Assistant Prof. Dr. Manuel Wimmer, Head of CDL-MINT: “In Industry 4.0 projects, physical systems are given a virtual representation in order to be able to communicate with other components via the Internet of Things (IoT), whereby the interactivity of the implemented components is assumed. We were able to successfully demonstrate our extended approach using the PiCar mobile robot.” The robot’s control software uses the “Systems Modeling Language” (SysML), which allows communication sequences and interactions between different components to be displayed visually over time. Using SysML, so-called sequence diagrams are created by which messages and data exchanged between interaction partners can be visualized and analyzed.

New data reduction method

This new approach is called “Sequence Pattern Mining” (SPM) and enables automatic recognition and abstraction of interaction patterns. However, this requires suitable models: planning models for the creation of complex systems and descriptive models for live analysis.

Peter Lieber, founder and owner of LieberLieber, says: “In our customer projects we see that sequence diagrams, especially in the area of Industry 4.0, are becoming increasingly complex and no longer manageable. We are therefore very proud of the new method being developed in this project that allows us to carry out analyses of live system behavior by means of targeted data reduction. This is an important requirement of the German Industry 4.0 platform for the further development of such systems.”

PiCar proves the efficiency of the new approach

For Peter Lieber, the joint development of PiCar represents an important step in the implementation of industry 4.0 scenarios with model-based development. “Even very powerful modeling platforms such as Enterprise Architect are reaching their limits in view of the large amounts of data generated during live operation. With our new SPM method, we were able to show how the mass of data can be reduced in a targeted manner. Model-based development, which is increasingly at the heart of Industry 4.0 solutions, can thus help to better manage complexity and handle data streams in an orderly manner. We will therefore continue to work closely together on such approaches so that we can quickly provide the industry with suitable tools.”

Continuing this research work, a six-axis robot controlled by the Hedgehog microcontroller will be used in the CDL-MINT project from 2018 onwards. This controller was developed by “Practical Robotics Institute Austria” (PRIA) at the TGM Vienna in the research project “RoboUML” on the basis of Enterprise Architect and LieberLieber Embedded Engineer.

Christian Doppler Laboratories drive high-level application-oriented basic research, an environment wherein outstanding scientists cooperate with innovative companies. The Christian Doppler Research Association is regarded internationally as an example of best practice in promoting this cooperation. Christian Doppler laboratories are jointly financed by the public sector and the participating companies. The most important public sponsor is the Federal Ministry of Science, Research and Industry (BMWFW). CDL-MINT integrates the two industrial partners CertiCon (the “Cooperative Simulation Megamodels” module) and LieberLieber (the “Reactive Model Repositories” module).

More about Christian Doppler Labors